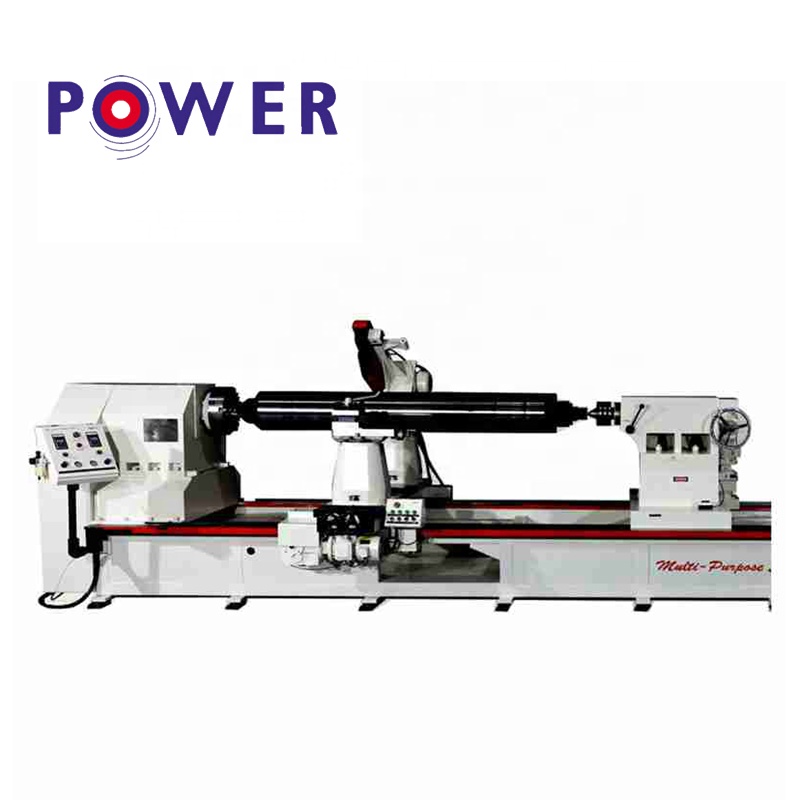

Product description

1. The PCM-1660 model is suitable for renewing Industrial Rubber Rollers.

2. Removing old rubber by special ring cutter.

3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.

4. Perfectly keeping the original dynamic balance of the roller core.

5. Giving more reliable guarantee for the bonding of the rubber and steel cores.

6. Saving costs and labors with this improved production system.

MODEL | SPECIFICATION | MAX. DIAMETER | MAX. LENGTH | CUBAGE | POWER |

LIGHT SCALE | PCM-4030 | 15.7" 400mm | 118" 3000mm | 197"*63"*55" 5m*1.6m*1.4m | 8.5KW |

MEDIUM | PCM-6040 | 24" 600mm | 157.5" 4000mm | 236"*70"*59" 6m*1.7m*1.5m | 8.5KW |

STANDARD | PCM-8040 | 31.5" 800mm | 157.5" 4000mm | 236"*71"*63" 6m*1.8m*1.6m | 11.9KW |

HEAVY DUTY | PCM-1250 | 47.2" 1200mm | 196.9" 5000mm | 307"*79"*63" 7.8m*2.0m*1.7m | 19KW |

LARGE SCALE | PCM-1660 | 63" 1600mm | 236.2" 6000mm | 339"*102"*71" 8.6m*2.6m*1.8m | 23KW |

PCM Multi-Purpose Stripping Machine is specially researched, developed and designed for treating old Rubber Rollers. PCM Multi-purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process. After the belt grinding process, the surface is not required to be cleaned by any solvent, the balance of the roller core is prevented from being damaged. Therefore, production efficiency will be improved, cost and labor will be saved. Most importantly, the bonding of the rubber and the roller core will be secured by this procedure.

Packaging & Shipping

Packing details:

1. Outside package: Standard export wooden cases

2. Inner package: Stretch film

Delivery time:

Within 2-4 weeks

Equipment video:

Shipping photos:

Related News

Submitted successfully

We will contact you as soon as possible