The Versatile Role of Rubber Roller Covering Machines in Modern Industries

Introduction: Rubber roller Covering machines have witnessed a revolution in recent years, revolutionizing the process of packaging various materials. These machines offer precise and efficient wrapping of products, ensuring their protection during storage, transportation, and handling. With advancements in technology, rubber roller wrapping machines have become indispensable in industries such as logistics, manufacturing, and warehousing. This article will explore the importance, benefits, and advancements in rubber roller

Rubber roller Covering machines, also known as stretch wrapping machines, have emerged as a vital tool in modern industries. These machines provide efficient and secure packaging solutions for various products, ensuring their protection during storage, transportation, and handling. With advancements in technology, rubber roller wrapping machines have become indispensable in industries such as logistics, manufacturing, and warehousing. This article will explore the importance, benefits, and advancements in rubber roller wrapping machines.

1. Increased Efficiency in Packaging: One of the primary benefits of rubber roller wrapping machines is their ability to enhance packaging efficiency. These machines automate the packaging process, eliminating the need for manual labor and reducing human error. With adjustable wrapping parameters, such as wrapping speed, tension control, and film overlap, these machines ensure consistent and uniform wrapping of products. This results in a faster, more efficient packaging operation, saving both time and labor costs.

2. Secure and Reliable Packaging: Rubber roller wrapping machines provide secure and reliable packaging for various products. By tightly wrapping products with stretch film, these machines create a protective barrier that prevents damage or contamination during transportation and storage. The ability to adjust tension control allows for flexibility in wrapping different types of products, ensuring optimal protection. This reliable packaging significantly reduces the risk of product damage, increasing customer satisfaction and minimizing costly returns.

3. Versatility in Wrapping Options: Rubber roller wrapping machines offer versatility in wrapping options, catering to the diverse needs of different industries. These machines can handle various product shapes, sizes, and weights, making them suitable for packaging items ranging from small boxes to large pallets. With customizable wrapping programs, operators can adjust parameters such as wrapping patterns, film thickness, and stretch levels to meet specific packaging requirements. This adaptability allows rubber roller wrapping machines to accommodate different packaging scenarios, enabling efficient and customized solutions.

4. Cost Reduction: Implementing rubber roller wrapping machines can lead to significant cost reductions for businesses. By automating the packaging process, these machines eliminate the need for manual labor, reducing staffing costs and minimizing the risk of injuries associated with manual handling. Additionally, the use of stretch film, which is cost-effective, reduces the overall packaging material expenses compared to traditional packaging methods. Moreover, the secure and tightly wrapped packaging reduces the risk of product damage, minimizing potential financial losses and increasing profitability.

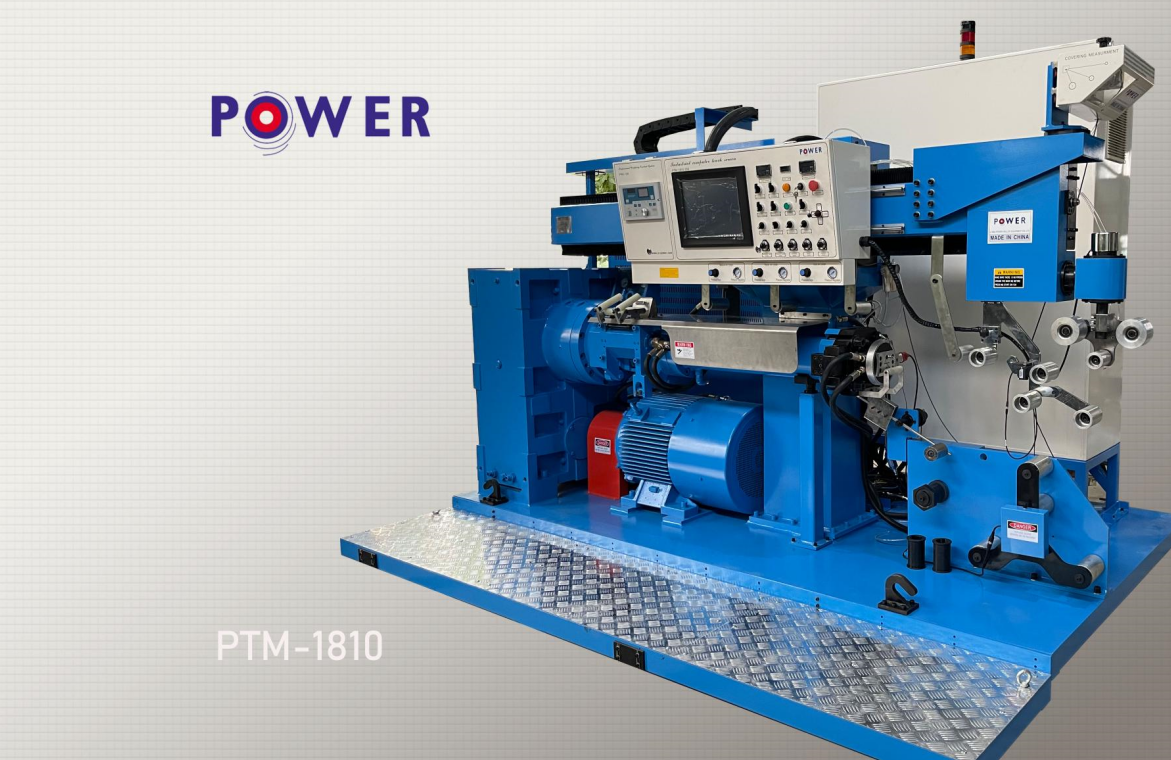

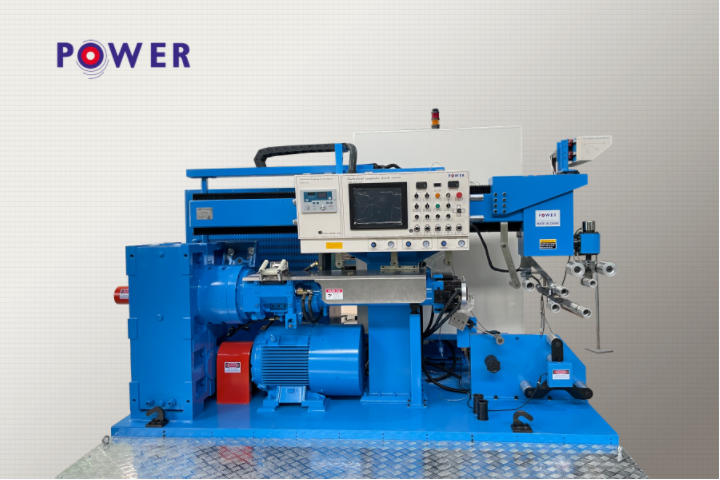

5. Technological Advancements: Advancements in technology have led to several improvements in rubber roller wrapping machines. For instance, intelligent control systems and touchscreen interfaces provide more user-friendly operation and advanced monitoring capabilities. These systems allow operators to easily adjust parameters, monitor the wrapping process in real-time, and diagnose and resolve any issues promptly. Additionally, the integration of sensors and automation reduces the need for manual intervention, ensuring precise and consistent wrapping results.

6.Environmental Considerations: Rubber roller wrapping machines contribute to environmental sustainability by promoting the efficient use of packaging materials. The use of stretch film in the wrapping process reduces the overall packaging waste compared to other bulky and non-recyclable materials. Additionally, some rubber roller wrapping machines come equipped with film pre-stretch mechanisms that stretch the film before wrapping, reducing film consumption and minimizing environmental impact.

Conclusion: Rubber roller Covering machines have revolutionized the packaging process in modern industries. These machines offer increased efficiency, secure packaging, versatility, and cost reduction. With technological advancements, they provide more user-friendly interfaces and advanced monitoring capabilities, enhancing their functionality. Moreover, their contribution to environmental sustainability through the efficient use of packaging materials makes them a valuable asset for businesses. As industries continue to evolve, rubber roller wrapping machines will remain essential in providing efficient and reliable packaging solutions.