Introduction to Rubber Roller Wrapping Machine and Its Application

Rubber roller wrapping machines, also known as rubber roller covering machines, are specialized equipment used for covering rubber rollers with different materials, such as rubber, polyurethane, or silicone. These machines are widely used in industries such as printing, textile, paper, packaging, and plastic to improve the performance and lifespan of rubber rollers.

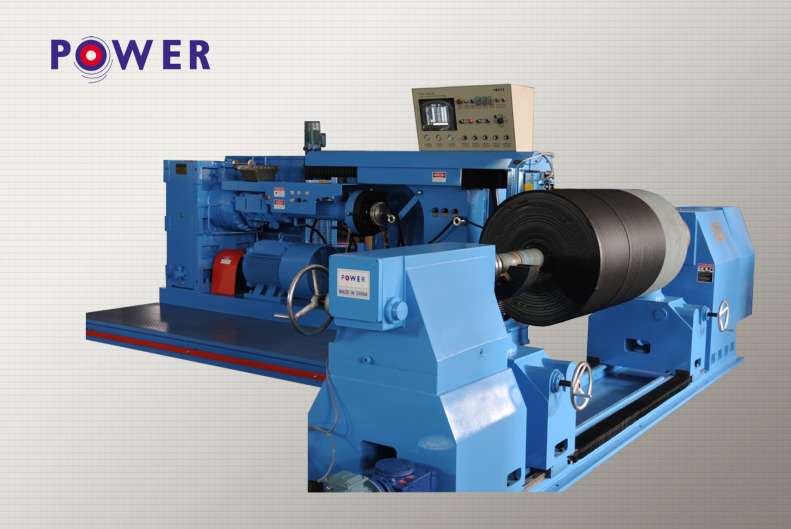

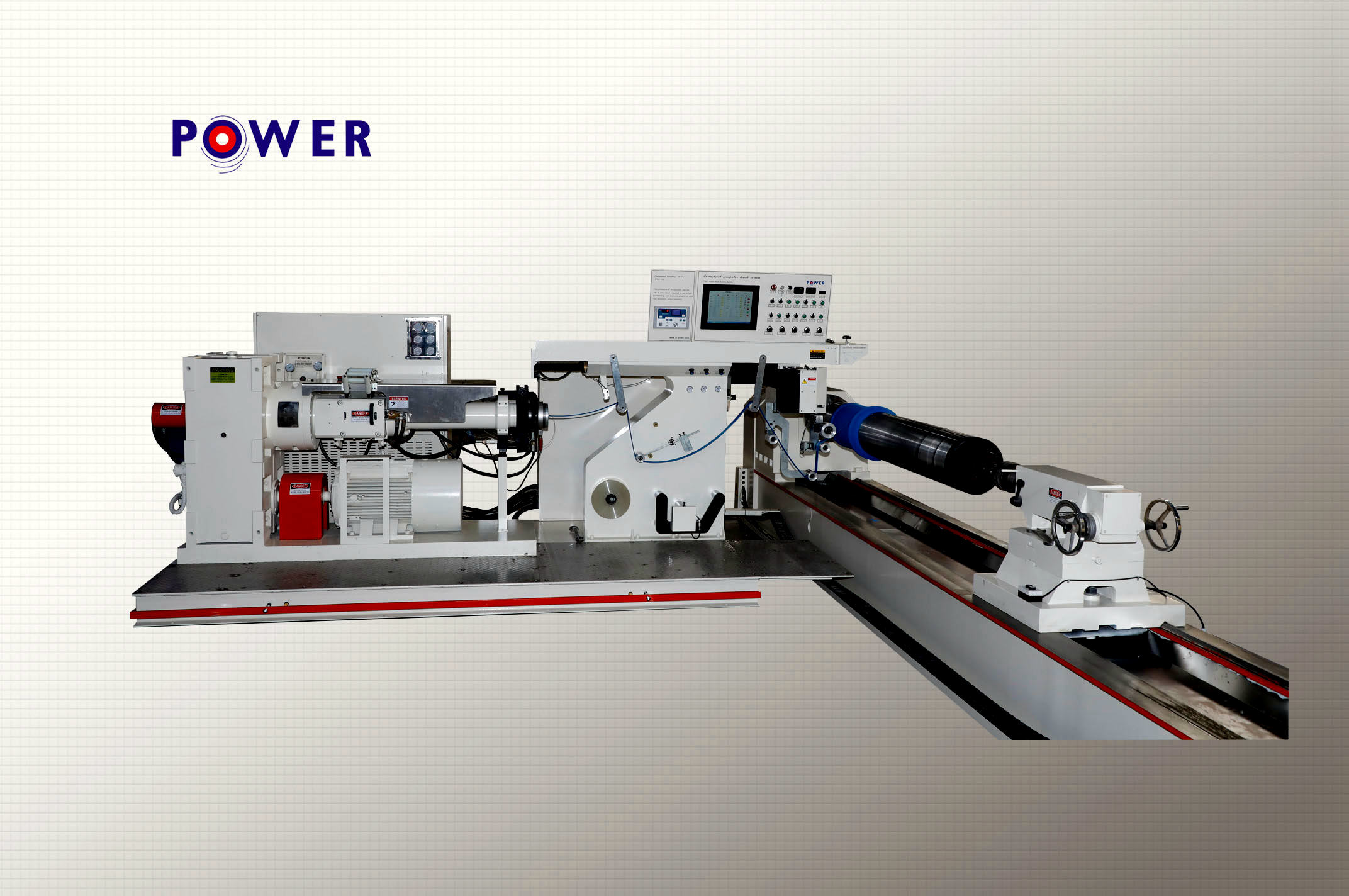

Rubber roller wrapping machines are designed to provide a seamless and uniform covering for rubber rollers. They are equipped with various components, including a base frame, a control panel, a roller support system, and a material dispensing system. The roller support system securely holds the rubber roller in place while it rotates, and the material dispensing system applies the covering material onto the roller surface. The control panel allows operators to adjust the machine settings, such as the speed, tension, and thickness of the covering material.

The application of rubber roller wrapping machines is diverse. In the printing industry, rubber rollers are crucial components for ensuring smooth and precise paper feeding. By applying a new layer of rubber coating onto worn-out or damaged rollers, the wrapping machine can restore the roller's grip and improve the quality of the printed output. Similarly, in the textile industry, rubber rollers are used for guiding fabrics or yarns during the production process. The wrapping machine can apply a layer of anti-slip or heat-resistant material onto the rollers to enhance their performance and durability. In the packaging industry, rubber rollers are essential for conveying and guiding materials. The wrapping machine can apply a wear-resistant or anti-static material to the rollers, preventing damage to the packaging materials and improving the overall efficiency of the packaging process. Additionally, rubber roller wrapping machines have applications in industries such as paper manufacturing, plastic processing, and metal coil handling, where rubber rollers are used for various purposes.

The benefits of using rubber roller wrapping machines are significant. Firstly, by applying a new layer of covering material onto rubber rollers, the wrapping machine can extend their lifespan and reduce the frequency of roller replacement, thus saving costs for manufacturers. Secondly, the wrapped rollers can improve the performance and accuracy of the production process. For example, in the printing industry, the wrapped rubber rollers can provide better paper feeding control and reduce the risk of paper jams or misalignment. Thirdly, the covering material can enhance the surface properties of the rubber rollers, such as anti-slip, anti-static, or heat-resistant characteristics, depending on the specific requirements of the industry. Lastly, the precise control and automation features of rubber roller wrapping machines allow for easy operation and reduce the risk of human error.

In conclusion, rubber roller wrapping machines are essential equipment for covering rubber rollers with different materials in various industries. By extending the lifespan of rubber rollers, improving their performance, and enhancing the quality of the production process, these machines contribute to the efficiency and reliability of manufacturing operations. The continuous development of rubber roller wrapping machines will further advance the capabilities and applications in the industries they serve.