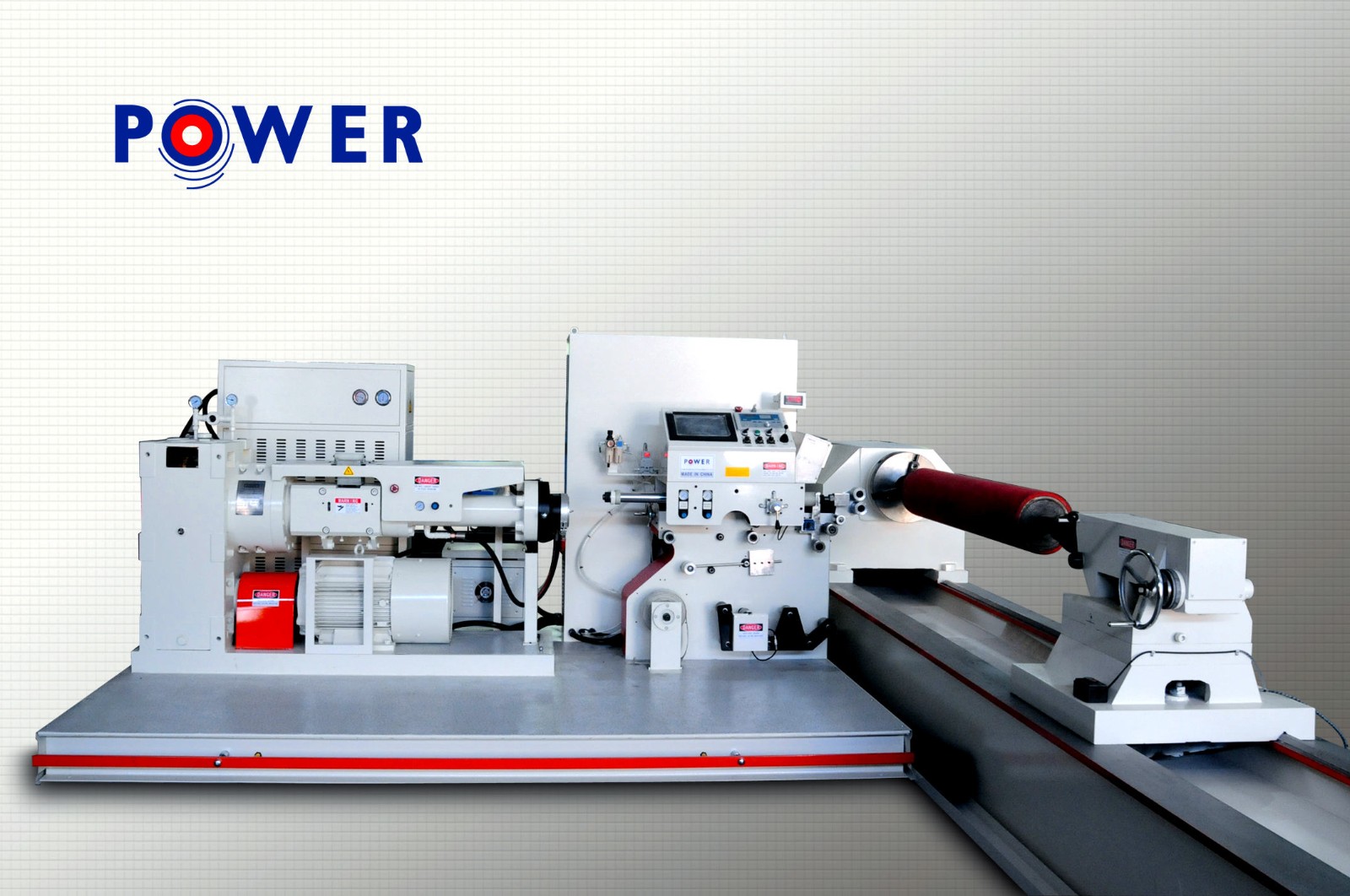

Introduction to Rubber Roller Covering Machine

Rubber roller covering machines, also known as roller wrapping machines, are essential tools used in various industries for covering rollers with different types of rubber materials. These machines provide a cost-effective and efficient way to protect and enhance the performance of rollers used in different applications. In this article, we will explore the features, working principle, benefits, and applications of rubber roller covering machines.

Features of Rubber Roller Covering Machines: Rubber roller covering machines come in different sizes and configurations to accommodate various roller sizes and shapes. Some key features of these machines include:

Durable construction: Rubber roller covering machines are typically made of high-quality materials to ensure durability and longevity.

User-friendly design: These machines are designed for easy operation, with user-friendly controls and settings.

Precision covering: Rubber roller covering machines ensure precise and uniform covering of rollers for optimal performance.

Versatile applications: These machines can cover rollers with different types of rubber materials, such as silicone, polyurethane, and natural rubber.

Working Principle of Rubber Roller Covering Machines: Rubber roller covering machines operate by wrapping a rubber material around a roller using a series of rollers, tension systems, and heating elements. The process involves the following steps:

Preparing the roller: The roller surface is prepared by cleaning and sanding to ensure proper adhesion of the rubber material.

Wrapping process: The rubber material is fed into the machine and wrapped around the roller using controlled tension and pressure.

Heating and curing: The covered roller is then subjected to heat to cure the rubber material and ensure a strong bond with the roller surface.

Trimming and finishing: Once the covering process is complete, the excess rubber material is trimmed, and the roller surface is finished to meet the required specifications.

Benefits of Rubber Roller Covering Machines: Rubber roller covering machines offer several benefits to industries that use rollers in their processes, including:

Extended roller life: By providing a protective layer of rubber, these machines help extend the lifespan of rollers and reduce wear and tear.

Enhanced performance: The rubber covering improves the grip, traction, and durability of rollers, resulting in improved performance and efficiency.

Customization options: Rubber roller covering machines allow for customization in terms of material selection, hardness, and surface finish to meet specific application requirements.

Cost-effective solution: Investing in a rubber roller covering machine can be a cost-effective solution compared to replacing rollers frequently due to wear and damage.

Applications of Rubber Roller Covering Machines: Rubber roller covering machines are commonly used in industries such as printing, packaging, textiles, and manufacturing. Some common applications include:

Printing industry: Covering printing rollers with rubber material to improve ink transfer and print quality.

Packaging industry: Covering conveyor rollers with rubber to enhance grip and reduce slippage.

Textile industry: Covering rollers used in textile machinery to improve traction and prevent fabric slipping.

Manufacturing industry: Covering rollers in various machinery to improve product handling and processing.

In conclusion, rubber roller covering machines play a crucial role in enhancing the performance and lifespan of rollers used in different industries. These machines offer a cost-effective and efficient solution for covering rollers with rubber materials, providing numerous benefits to industries that rely on rollers for their operations. With their versatility and precision, rubber roller covering machines are essential tools for maintaining and improving roller performance in various applications.