Introduction and types of rubber extruders

Rubber extruder is a basic equipment in the rubber industry and one of the key equipment that affects product quality. It plays a very important role in the production process of tires and rubber products. The development of rubber extruders abroad has gone through stages such as plunger extruders, screw type hot feed extruders, ordinary cold feed extruders, main and auxiliary thread cold feed extruders, cold feed exhaust extruders, pin cold feed extruders, and composite extruders. Rubber extruders are used for molding, filtering, and rubber wrapping of rubber semi-finished products. The structural characteristics are that the screw and inner sleeve are made of nitrogen treated steel, which has good wear resistance and corrosion resistance

The screw extrusion of rubber compounds in rubber extruders is one of the oldest fields of extrusion technology, which can be traced back to the 19th century. Rubber extruders are significantly different from thermoplastic extruders. Firstly, rubber extrusion is carried out at a lower temperature (up to 130 ° C). Secondly, rubber extrusion often involves the addition of rubber strips (only in exceptional cases), which do not undergo phase change or significant thickening in the screw extruder system. Unlike thermoplastic, which undergoes processing at temperatures of 180 ^ -300 ° C (or higher) in the screw extruder, low-density solid pellets are often added to the extruder. When the pellets move forward along the screw, they do not undergo phase change or significant thickening. The molten well is compacted

Rubber extruders are usually classified into hot feed and cold feed machines. In hot feed extruders, the mixed rubber is heated by the mechanical action of the open mill, and these heated rubber strips are cut and continuously fed to the extruder. In cold feed screw extruders, composition of rubber,china rubber corona pressure roller,room temperature rubber strips are added to the extruder. Rubber extruders are also often classified according to whether they are used for exhaust

Types of rubber extruders

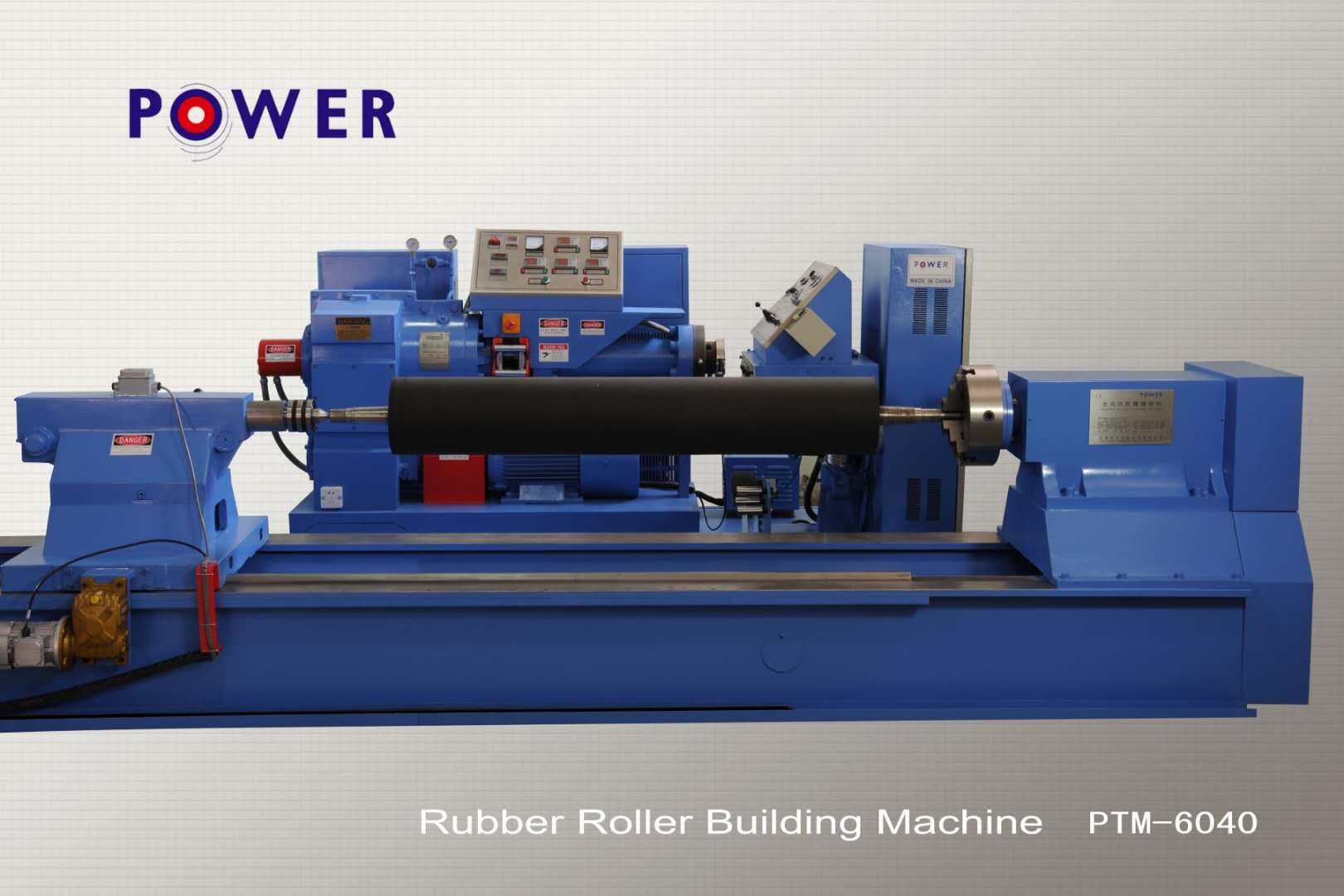

Rubber extruder is a basic equipment in the rubber industry and one of the key equipment that affects product quality. It plays a very important role in the production process of tires and rubber products. The development of rubber extruders abroad has gone through stages such as plunger extruders, screw type hot feed extruders, ordinary cold feed extruders, main and auxiliary thread cold feed extruders, cold feed exhaust extruders, pin cold feed extruders, and composite extruders,cnc cylindrical grinder machine

Rubber extruders are divided into plunger type, screw type, ordinary type, cold feed type, pin type, and composite type