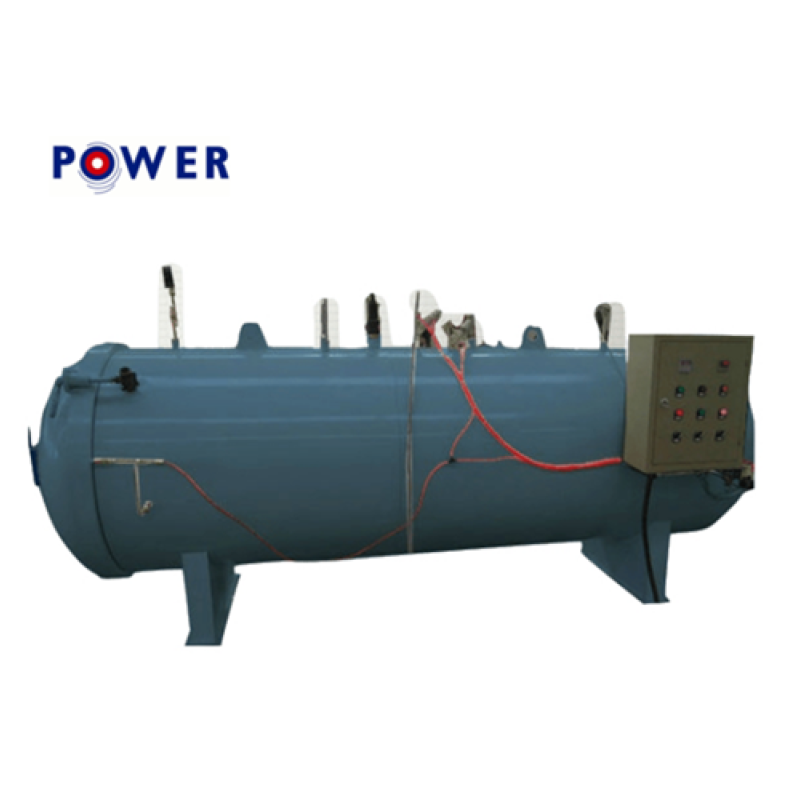

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2.

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Product description1.

Contact Now

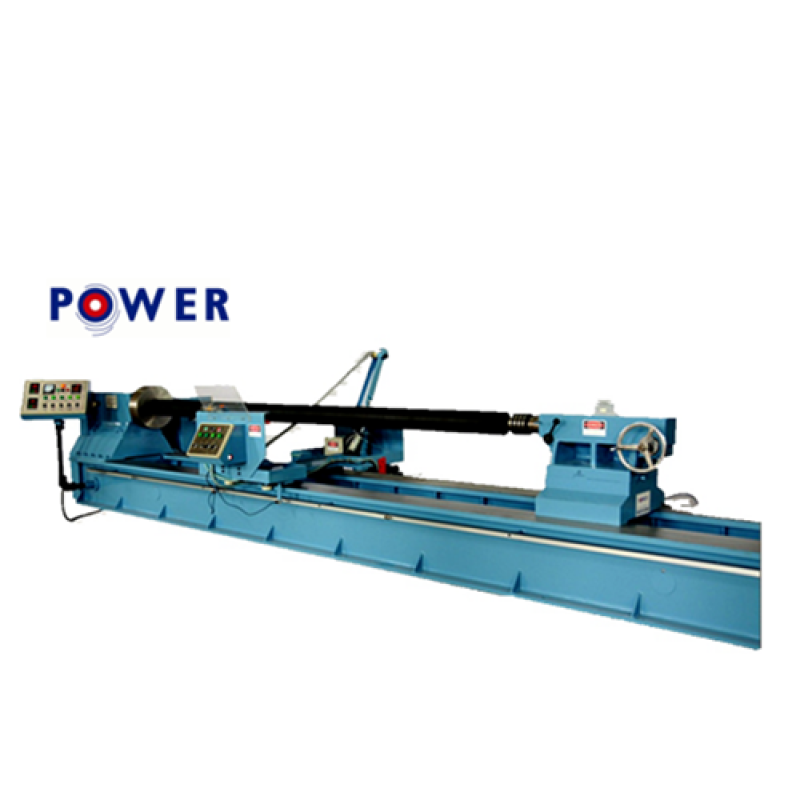

Product Description:Mainly used for balance verification of large and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and other rotating workpieces.The machine adopts ring belt drive or gear box universal joint transmission, and frequency conversion motor drive to ensure the balanced quality and precision of the workpiece.The machine has the characteristics of wide speed range, large driving power and high working efficiency. Model NumberPHQ-3000HPHW-3000H2460-10000HTransmissionBelt DriveUniversal JointUniversal JointWorkpiece weight range (kg)3000300010000Workpiece Ma

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistanceApplications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such&n

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

PPM Series Rubber Roller Polishing Machine is an important equipment for the rubber roller refining processe. The Polishing machine is the ideal finish processing equipment for the high-end printing rubber rollers, and rollers with a high requirement on their surface. By choosing different grit size of the grinding belts, it can reaches different requirements on the surface smoothness.Jinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

Features:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature performance ,oil resistance ,UV resistance Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers Shipping:

Contact Now

Functions:1 ozone resistance ,climate developing antique resistance ,chemical resistance2 warmth growing older resistance ,low temperature normal overall performance ,oil resistance ,uv resistancePackages:· automobile sectors:which consist of hoses, tubings, immoderate temperature timing belts· enterprise sectors :along side seals, lingings, printing rollersShipping:

Contact Now

Web Press Rubber Roller For PrinterWith the attitude of being professional and sincere, Power Company produces high-quality rubber rollers closely following sci-tech requirement of the times. You can be assured that each product is of reliable quality, for we are extremely strict with the production processing of rubber roller.

Contact Now

Product description1. this equipment is designed as a comply with up device of our psm collection for the rubber curler floor refining system.2. meeting essential requirements at the floor smoothness via choosing the abrasive band with distinctive granularity.3. the geometric length of rubber curler will remain unchanged.4. the working device is easy and clean-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Factory Price Rubber Roller PolisherMore than 8 merchandise have been provided countrywide or shandong provincial stage product prizes and three scientific-studies achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Equipment video:Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5.

Contact Now

Factory Price Rubber Roller PolisherMore than eight products have been awarded National or Shandong Provincial level product prizes and three scientific-research achievement prizes. Packaging & ShippingPackaging detail of Factory Price Rubber Roller Polisher : 1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail: Within 2-4 weeks Our Services1. Installation service.2. Maintenance service.3. Technical support online service provided.4. Technical files service provided.5. On-site training service provided.6.

Contact Now

Product description1. this gadget is designed as a follow up device of our psm collection for the rubber roller floor refining device.2. assembly critical requirements on the ground smoothness thru selecting the abrasive band with specific granularity.3. the geometric length of rubber roller will stay unchanged.Four. the running device is simple and smooth-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product Description:Specially used for stability verification of massive and medium-sized motor rotors, blowers, pump impellers, dryers, rollers and different rotating workpieces.The device adopts ring belt power or gear field familiar joint transmission, and frequency conversion motor drive to ensure the balanced nice and precision of the workpiece.The gadget has the characteristics of huge pace range, huge driving energy and high working performance. Model NumberPHQ-3000HPHW-3000H2460-10000HTransmissionBelt DriveUniversal JointUniversal JointWorkpiece weight range (kg)3000300010000Workp

Contact Now

Applications:· Automobile sectors:such as hoses, tubings, high temperature timing belts· Industrial sectors :such as seals, lingings, printing rollers High Quality Rubber Roller Raw Material / Top Quality Rubber Roller Raw Material / Good Quality Rubber Roller Raw Material / Best Quality Rubber Roller Raw MaterialProduct descriptionFeatures:1 ozone resistance ,weather aging resistance ,chemical resistance2 heat aging resistance ,low temperature perfor

Contact Now

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

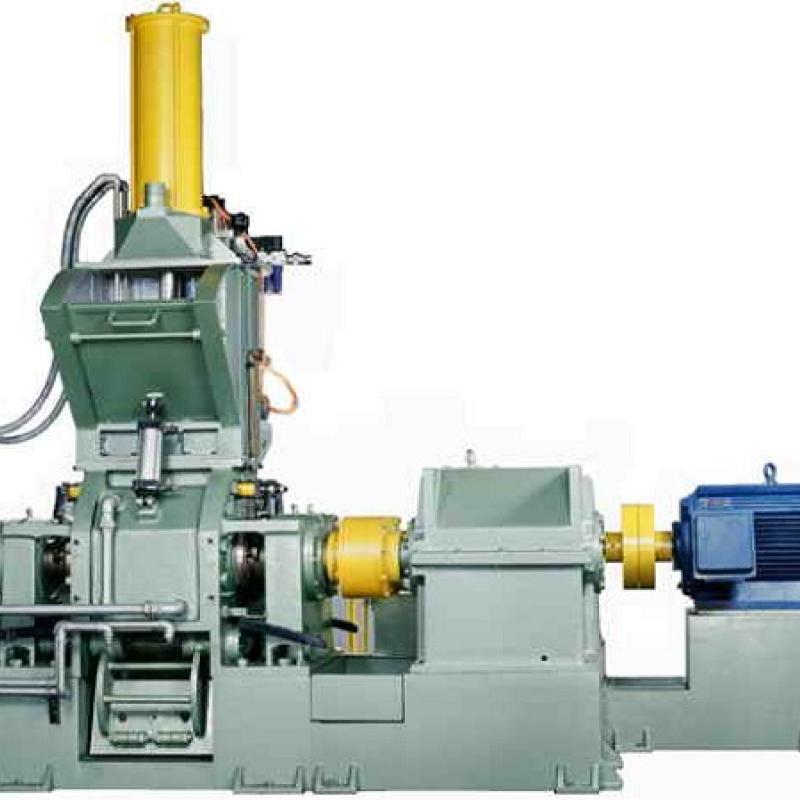

Banbury Rubber machineBanbury rubber device is a type of high electricity clearance mixing device evolved on the premise of the open mixer milll.consequently, the emergence of banbury rubber machine is a rubber machinery, an vital achievement, nevertheless is the plastic refining and mixing of the everyday critical equipment, continues to be in consistent improvement and improvement. Our Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Spare parts replacement and repair

Contact Now

PTM-1510 Printing Rubber Roller ExtruderJinan Power Rubber Roller Equipment Company`s technology is intended to increase the productivity of rubber roller industry. PTM-1510 rubber roller extruderThese models are suitable for processing big type paper making and mine transmission rubber rollers and other industrial transmission rollers. Extruder is especially designed for the rubber roller manufacture. These two modes are equipped with E350CS power extruder and the industrial cooling system. It equip with high degree automatic control system.

Contact Now